today's hyper-aggressive manufacturing landscape, precision and efficiency are the cornerstones of accomplishment. regardless of whether you are a budding entrepreneur from the cosmetics sector, a seasoned veteran inside the food stuff and beverage sector, or simply a slicing-edge pharmaceutical enterprise, the proper liquid filling equipment can be the pivotal factor that sets you aside. choosing the best liquid filling equipment company is the first step in securing an extended-phrase trustworthy asset. envision cutting down item squander, streamlining your output line, and regularly providing properly crammed products that exceed consumer expectations. this is not simply a dream; It truly is an achievable reality with the best liquid filling technology. As we head into 2025, the industry is teeming with revolutionary solutions, Every single promising to revolutionize your filling procedures. But with numerous possibilities available, how do you discern the genuinely exceptional from the basically ample? This article cuts with the sounds and offers you having a curated array of the five very best liquid filling equipment poised to dominate the market in 2025, making sure you make an informed conclusion that propels your organization forward. We’ll examine their strengths, weaknesses, and exceptional functions, arming you Along with the knowledge to pick the perfect equipment to satisfy your unique manufacturing requires.

Table of contents:

comprehension the critical Criteria for Liquid Filling Machines

Jiaren Machinery Single-Head Magnetic Pump Filling device

CDA CDA-2000 collection Semi-Automatic Filling equipment

Sorbent methods FlexiFill Pro

Accutek Packaging AccuFill SA-a hundred and fifty

IC Filling methods LiquiBot X3

knowing the vital Criteria for Liquid Filling devices

ahead of diving into the precise models, It is essential to establish a framework for analysis. What actually would make a liquid filling equipment jump out from the group? according to in depth business research, consumer comments, and specialist Assessment, we've recognized the subsequent vital standards:

Filling Accuracy: Precision is paramount. Ideally, a prime-tier equipment ought to boast an accuracy of ±one% or far better. Inaccurate filling leads to products wastage, inconsistent fill levels, and prospective regulatory problems, all of which can negatively impact your base line. try to find equipment with advanced sensors and Manage methods that be certain consistent and specific fills each time.

Operational relieve: A user-pleasant interface is significant for maximizing productivity. devices with intuitive touchscreens, pre-programmable configurations, and quick recipe changeover abilities minimize downtime and lower the educational curve for operators. the opportunity to shop and remember routinely utilised options is An important time-saver.

Versatility: The perfect liquid filling machine need to be adaptable to a wide array of liquids and container dimensions. This flexibility allows you to cope with diverse products lines without needing many equipment, maximizing your return on expense. think about the viscosity range the device can cope with, and also the sorts of containers it might accommodate (e.g., bottles, vials, pouches).

sturdiness & dependability: A robust and sturdy equipment minimizes upkeep costs and guarantees prolonged-time period operational performance. search for devices made from large-top quality resources, including stainless steel, that can stand up to the rigors of everyday use. think about the availability of spare components plus the producer's popularity for supplying reliable provider and assist.

Price tag-Effectiveness: The price of the machine ought to be justified by its general performance, characteristics, and very long-term Gains. even though the Original investment decision is essential, think about the total expense of ownership, such as upkeep, repairs, and likely downtime. A equipment that provides a robust harmony of options and value is the greatest worth proposition.

Let's take a look at the highest contenders during the liquid filling equipment market for 2025, inspecting their strengths, weaknesses, and distinctive characteristics:

Jiaren Machinery Single-Head Magnetic Pump Filling Machine

https://jiaren-machinery.com/

Main Strengths: This equipment stands out resulting from its advanced magnetic travel technologies and Outstanding precision. It's a workhorse while in the business and also the liquid filling machine maker is attaining Increasingly more recognition.

Magnetic travel technologies: The use of a seal-fewer magnetic pump eradicates the risk of leakage, rendering it perfect for dealing with superior-value or corrosive liquids, including crucial oils, serums, and chemical reagents. This engineering guarantees a clear and safe Operating atmosphere.

Ultra-substantial Accuracy (±0.five%): Equipped with superior-resolution stream sensors, this device ensures reliable and specific filling volumes, reducing solution squander and making certain uniform fill stages across all containers.

just one-Touch Recipe Switching: The seven-inch touchscreen means that you can retail store as much as one hundred pre-established parameters, enabling swift products changeovers without the require for manual calibration. This function substantially lowers downtime and enhances creation performance.

Multi-practical Adaptability: By simply shifting the filling head, this equipment can manage a variety of container measurements, from 5ml to 5L, which include PET bottles, glass bottles, and versatile tubes. This flexibility causes it to be well suited for various industries, together with cosmetics, food items, and substances.

Power effectiveness & lower sounds: Consuming fifteen% a lot less power than equivalent models and functioning at a noise volume of ≤60dB, this machine is ideal for tiny workshops, laboratories, and environments where by sounds air pollution is a concern.

Ideal For: tiny to medium-sized companies hunting for a functional, exact, and reputable liquid filling Resolution. Specially perfectly-suited to managing expensive or corrosive liquids.

User opinions: A distinguished skincare brand claimed a 40% reduction in filling losses and a discount in product line changeover time to below ten minutes soon after utilizing the Jiaren machine.

CDA CDA-2000 sequence Semi-automated Filling equipment

https://cda-usa.com/

Key Highlights: This equipment excels in managing viscous liquids and presents Outstanding modularity.

Pneumatic Piston Pump procedure: precisely made for high-viscosity liquids, like honey, jams, and sauces, this system can take care of liquids with viscosities as many as fifty,000 cP.

Modular structure: The modular composition permits the fast addition of weighing modules or vacuum suction equipment, boosting its features and adaptability. This enables corporations to tailor the machine to their certain needs.

perfect for: meals processing, beverage manufacturing, and nutraceuticals the place viscous liquids are commonly handled.

The liquid filling machine on the market are available on its official Web-site, with fantastic client evaluations.

Sorbent programs FlexiFill Pro

https://www.sorbentsystems.com/index.html

Unique capabilities: concentrates on sterile filling capabilities for pharmaceutical and professional medical purposes.

Sterile Filling technological innovation: Compliant with FDA polices, this equipment integrates a HEPA filtration system, Assembly the stringent cleanroom benchmarks of your pharmaceutical and professional medical machine industries.

Elastomer Compatibility: Supports a wide array of liquid types, from aqueous options to viscous pastes, and will accommodate specialized containers including pre-stuffed syringes.

perfect for: Pharmaceutical businesses, healthcare unit manufacturers, together with other industries necessitating aseptic filling environments.

Accutek Packaging AccuFill SA-a hundred and fifty

https://www.accutekpackaging.com/

Main price: gives industrial-grade durability and sensible calibration characteristics.

Industrial-Grade sturdiness: Constructed with a comprehensive stainless steel frame website and ceramic pump, this equipment is made for steady 24/7 operation in demanding production environments.

clever Calibration program: Features an automated viscosity detection system that adjusts the filling speed in authentic-time to minimize foam technology.

perfect for: superior-volume output environments exactly where dependability and steady effectiveness are essential.

IC Filling methods LiquiBot X3

https://www.icfillingsystems.com/

Innovation Highlights: Integrates IoT connectivity and emphasizes Vitality effectiveness.

IoT Integration: permits remote monitoring of generation knowledge via a smartphone app, building serious-time reviews for analysis and optimization.

reduced-Carbon style: Consumes 30% much less Strength than regular styles and retains the ecu Union's Ecodesign certification, which makes it an environmentally dependable choice.

Ideal For: companies seeking to enhance their production processes by way of info-pushed insights and decrease their environmental footprint.

picking out the suitable Liquid Filling device: A Strategic final decision

picking the best liquid filling device requires mindful consideration within your particular wants, manufacturing volume, and price range. Here is a quick guideline to assist you make the ideal choice:

Small to Medium Batch, Multi-product or service creation: The Jiaren single-head magnetic pump filling machine is a wonderful choice as a consequence of its overall flexibility, simplicity of use, and low maintenance expenditures. Its power to handle many container sizes and liquid types can make it perfect for corporations with various product strains.

higher-Viscosity Liquids (meals/chemical substances): The CDA pneumatic piston pump program is specifically made for dealing with viscous liquids, making sure dependable and precise fills.

Sterile Filling necessities: The Sorbent devices FlexiFill Pro could be the ideal Resolution for industries requiring aseptic filling environments, such as pharmaceuticals and healthcare product production.

outside of the Machine: crucial issues

whilst the device alone is vital, remember to take into consideration these additional variables when creating your selection:

just after-Sales assistance: Ensure the manufacturer presents thorough following-product sales support, including installation, teaching, maintenance, and available spare elements.

Warranty: A comprehensive warranty shields your expenditure and offers peace of mind.

Customization choices: For those who have exclusive filling requirements, inquire about customization solutions to tailor the device to your particular demands.

Integration abilities: take into consideration how the equipment will integrate using your existing creation line and automation units.

The liquid filling field is continually evolving, driven by developments in automation, robotics, and facts analytics. As we shift ahead, count on to see much more advanced devices which provide higher precision, effectiveness, and flexibility. The mixing of IoT technological innovation will enable serious-time checking and optimization of manufacturing procedures, whilst AI-run devices will automate advanced responsibilities and increase General performance.the selection of the liquid filling device is surely an financial investment that impacts your long-term productiveness, profitability, and product good quality. deciding on the right liquid filling machine maker is essential for making certain a great partnership and support. By meticulously assessing your needs and thinking about the factors outlined in this article, you can also make an knowledgeable determination that sets your small business up for achievement in the yrs to come back. take a look at the revolutionary remedies made available from Jiaren equipment – where by precision fulfills efficiency. A custom-made Option tailored on your unique wants and perhaps request a free of charge sample filling assistance to view the difference firsthand.

Scott Baio Then & Now!

Scott Baio Then & Now! Tina Majorino Then & Now!

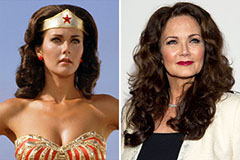

Tina Majorino Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!